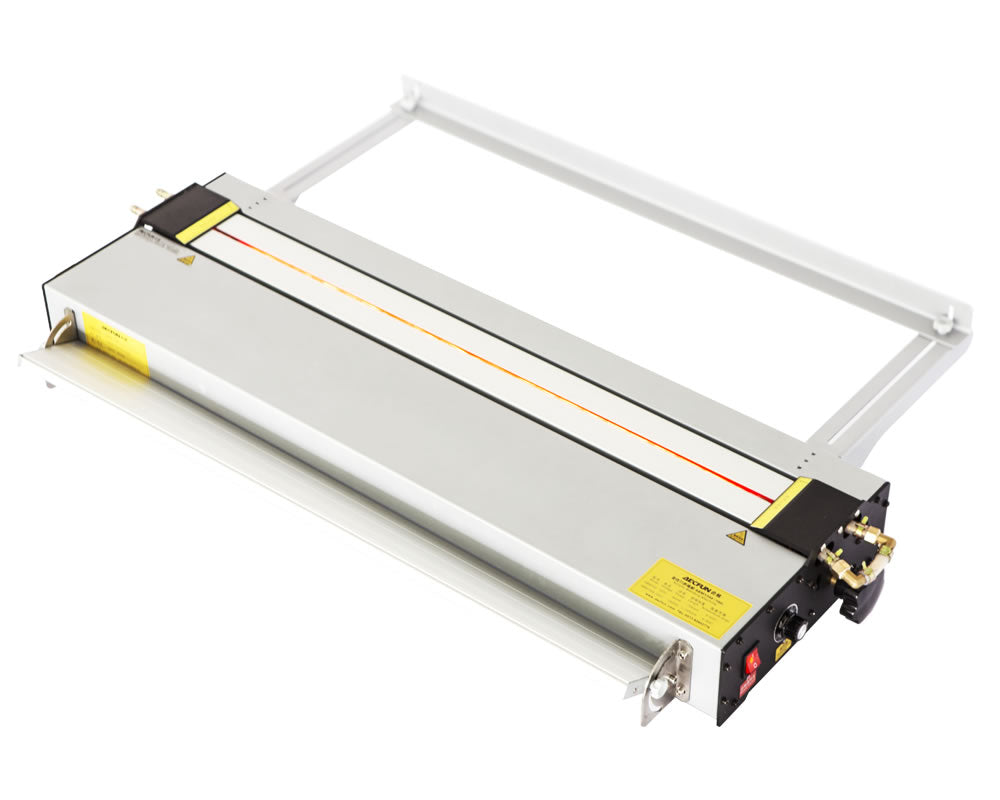

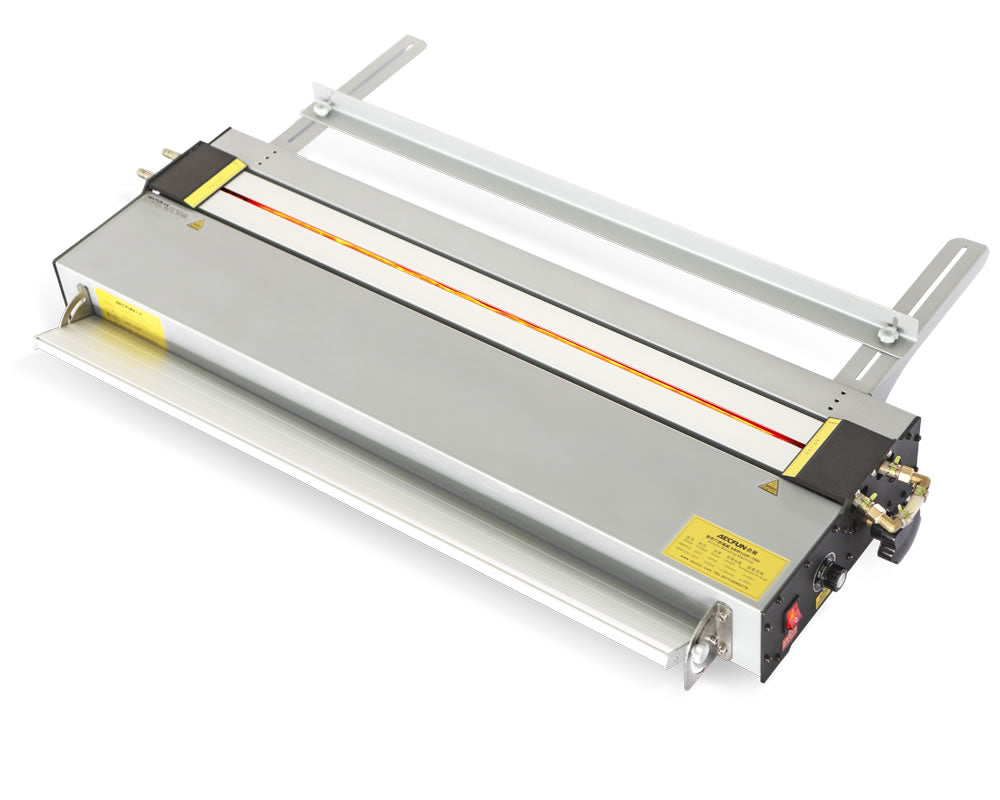

Acrylic Bending Machine ABM700/1300

For bending the plastic plate and make sign holders

Couldn't load pickup availability

Delivery

Delivery

Product

Product Introduction

Acrylic Bending Machine ABM700/1300 is an efficient and reliable small machine used to bend acrylic sheets into different shapes and angles. By heating the acrylic sheet to a plastic state, this machine can help users bend the material into the desired shape.

Acrylic Bending Machine ABM700/1300 is made of high-quality materials and manufacturing technology, with a sturdy and durable body structure. Its robust structure ensures long-term use, and both ABM700 and ABM1300 have the same functions. The difference is in their working size, with ABM700 having a maximum bending width of 650mm, and ABM1300 having a maximum bending width of 1250mm.

Perspex bending machine is equipped with the following functions:

Temperature control function, which can precisely control the heating temperature and ensure that the acrylic sheet is heated to the optimal bending temperature.

Heating width adjustment function, which ensures that sheets of different thicknesses are heated to the optimal bending width, thereby ensuring a high degree of accuracy in the bending effect.

Adjustable bending angle positioning function, which helps users accurately bend acrylic sheets to different angles.

Heating position positioning function, which can place the sheet on a preset positioning device to ensure that the heating position of each sheet is consistent when mass producing, ensuring consistent product quality.

Water cooling function, which cools the parts that do not need heating with water, ensuring that only the parts that need to be heated are softened, and other parts are not affected by temperature.

Plexiglass bender is widely used in various industries, such as signs, displays, and manufacturing, and can be used to make various products such as acrylic display racks, signs, and information boards. Its highly accurate bending effect allows users to easily create beautiful and practical products.

In addition, Acrylic Sheet Bender ABM700/1300 can also be used to bend other materials such as PC sheets, PP sheets, PE sheets, PS sheets, PET sheets, and PVC sheets, making it an essential multi-functional tool in the production and manufacturing process.

In conclusion, Acrylic Bending Machine ABM700/1300 is a necessary tool for thermal bending of any acrylic sheet or other plastic material. It can produce high-quality products at a lower cost, higher production efficiency, and in a more environmentally friendly manner.

Furthermore, it is worth mentioning that there are already 10,000+ customers worldwide using this machine.

-

Application Case

It is small and portable machine, so it can be used in anywhere.

-

Laboratory

It is used to bend plastic to make simple laboratory equipment. -

Billboard

It is used to bend acrylic for billboard in front of hotel, shop, mall, etc.

-

Display product

It is used to bend acrylic for displaying products such as appliances, mobile phones, cosmetics, magazines, shoes, etc. -

Table Sign

It is used to bend acrylic to make triangle table signs. Table sign is widely used in conference, hotel front desk agent, buffet.

-

Temperature adjustable

The temperature of infrared tube is ajustable according to different thickness of plastic sheet and max temperature is 600℃。 -

Water cooling device

Water in the tank is pumped to cool the heating tube to prevent it from being overheated and damaged.It ensures fast cooling and increases the life of the machine.

-

Adjustable heating gap width

According to different material and thickness of sheet, the gap width can be adjustable.The range of width is 0-20mm.

-

Standard configuration

Water pump and plastic tube.

-

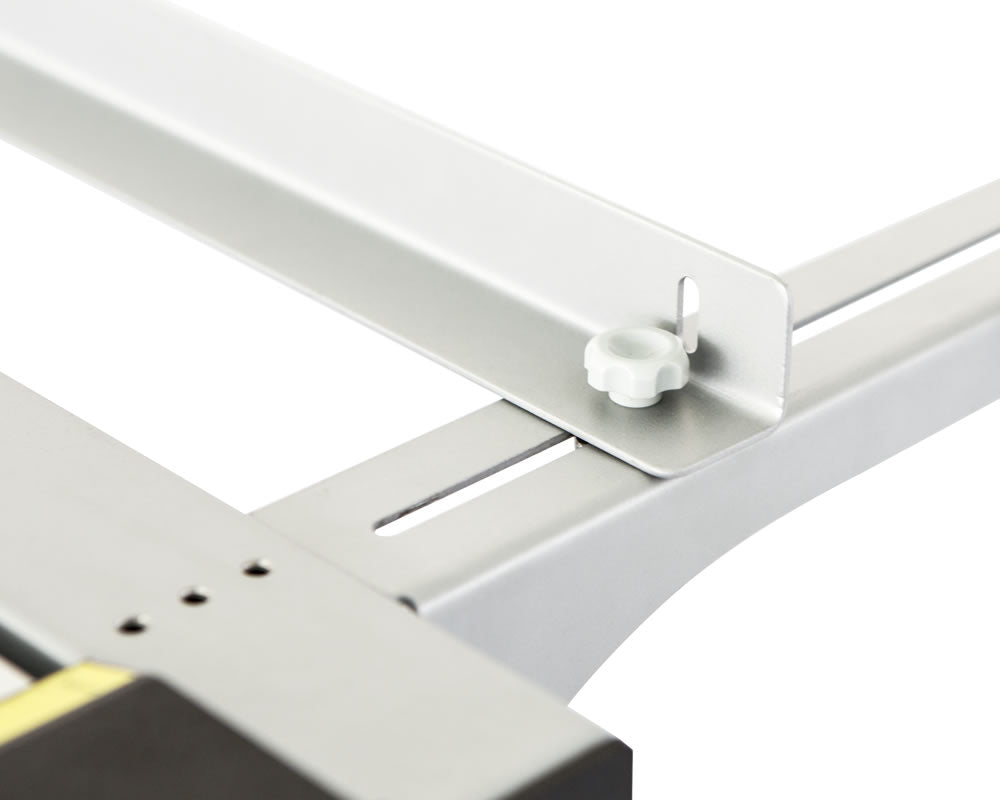

Same bended position

Adjust the length of the baffle to make the bended position of each acrylic plate the same. This feature can make the product more standardized and make manufacture more convenient.

-

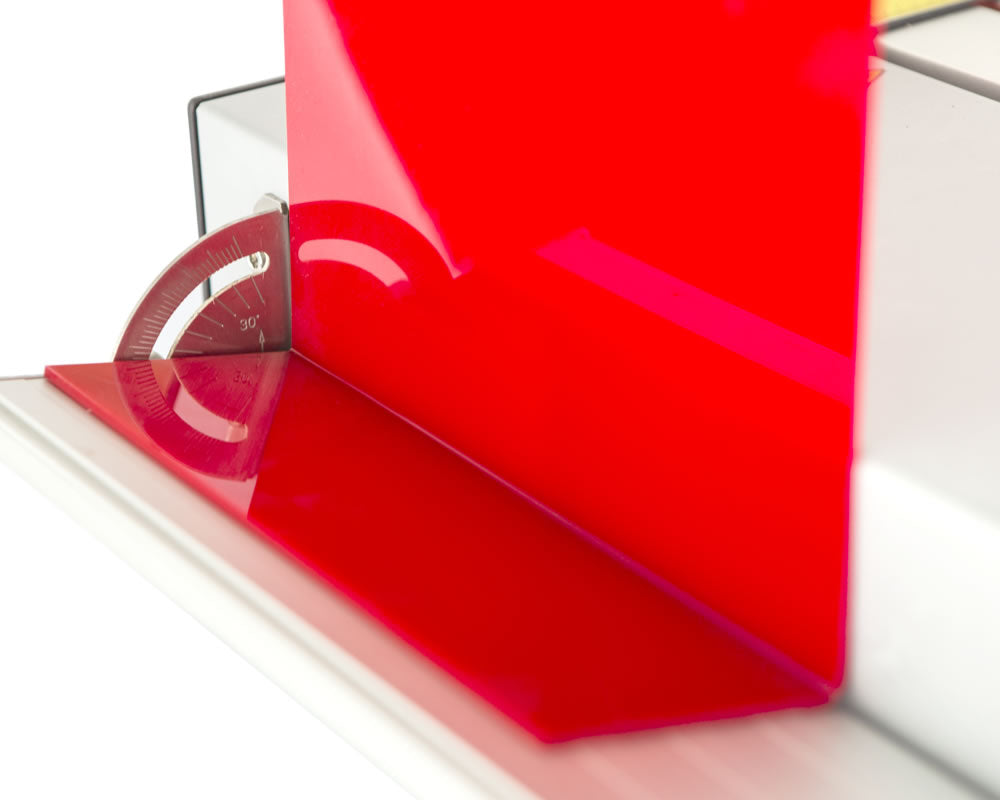

Same bended angle

The angle formed by the baffle and the back of the machine allows the bended angle of each plastic sheet to be the same. This feature can make the product more standardized and make manufacture more convenient.

Video

Parameter

| Signmate-Acrylic Bending Machine ABM | ||

|---|---|---|

| Product Name | Acrylic Bending Machine | |

| Product Model | ABM700 | ABM1300 |

| Working Principle | Thermal Forming | Thermal Forming |

| Applicable Length | ≦650mm | ≦1250mm |

| Applicable Thickness | 1-10mm | 1-10mm |

| Input Voltage | 110V/220V | 110V/220V |

| Working Voltage | 110V/220V | 110V/220V |

| Working Power | 1000W | 1500W |

| Temperature Range | ≤600℃ | ≤600℃ |

| Product Packing | ||

| Carton Size | Carton: 1250(W) x 430(D) x 185mm(H) | Carton: 1780(W) x 430(D) x 185mm(H) |

| Packing Quantity | 1pcs/ctn | 1pcs/ctn |

| Net Weight | 17kg | 26kg |

| Gross Weight | 23kg | 33kg |

| Product Shiping Specs | ||

| 20GP(General Purpose Container) | 264pcs | 188pcs |

| 40GP(General Purpose Container) | 552pcs | 384pcs |

| 40HQ(High Cube Container) | 644pcs | 448pcs |

| Express Service | Available | Available |

| Product Maintenance | ||

| Certification | CE Certification | |

| Warranty | 365D(exclude force majeure,aritificial factors) | |

FAQ

1. Q: What kind of material can it cut bend? What’s the applicable thickness?

A: Plastic plate like Acrylic, Plexiglas, PVC, PC,ABS, PP and so on ...etc. The applicable thickness is 1-10mm.

2. Q: Do you have the bigger one?

A: We have two models now. Only two models at present.ABM700: applicable length≤650mmABM1300: applicable length≤1250mm

3. Q: What’s the working theory of acrylic bending machine?

A: Softening and bending of plastic plate by far Infrared heating, shaped by hand or any mould.

4. Q: How many minutes should the user heat for 3mm sheet?

A: About 15 seconds.

5. Q: Can the machine heat multiple parts at same time?

A: No. Our machine has only one heating lamp, could heat and bend only one line at a time.

6. Q: How about the temperature? Is the temperature adjustable?

A: Temperature is adjustable ≤600℃ by the temperature button.

7. Q:Is the heating area adjustable?

A: Yes, according to sheet thickness and real requirement, heating range in 0-20mm.Generally, the sheet is thicker, the heating area need bigger. 3mm thickness sheet need heating width at least 8mm. 8mm thickness sheet need 20mm heating width.

8. Q: Does the machine have adjuster?

A: Yes, it has length position adjuster and angle adjuster in standard.

9. Q: Can the mahine bend big arc?

A: No. Is has only single heating lamp, main fuction is to bend angle. It is suggested using oven heating to make big arc.

10. Q: Can it be customized to 2.4m?

A: No. The current heating lamp could not achieve the requirement of stable quality and heating temperature.

11. Q: There is white foam under heating lamp. Does it need to take out before using the machine?

A: No. The object is for protecting the heating lamp and to insulated heating during working. It is heat-resisting material.

12. Q: Does it have input voltage in 110V?

A: Yes. Two voltages are available, 220V and 110V. Generally, some European countries and China is in 220V, North America and Japan is 110V. Pls confirm with sales before placing the order.

13. Q: Can the plug be changed to any countries’ standard?

A: Normal plug has 4version, E.U plug, British plug, U.S plug, and C.N plug. If indeed has other demand, pls send exact picture to sales for further confirmation. If we could buy from Chinese market, we could change as your demand.

14. Q: How does the water cooling system working?

A: The machine has 1pc water pump and 2pcs water pipes in standard. To fullfill the water in any water tank or bucket, connect the pipes with water pump, and put the water pump into the water, then turn on the switch. The water pump will push the water into machine inner through the pipes. The water temperature will rise during the working time. To acheive better cooling effect, please exchange the water when you feel the water is heated by your hand or the water temperature is up to 50℃.

15. Q: Is the water tank included?

A: No. User could use water tank or bucket with capacity ≥20L.

16. Q: The water temperature will be heated after long time work. Is there any method to reduce the water exchange time?

A: It is suggested to use big water tank or bucket. Or put some ice into the water to slow down water heated speed.

17. Q: Does the machine has fans cooling?

A: Yes, fans are installed. It has holes under and in the side of machine, helps to cooling and extending machine life.

18. Q: What’s the warranty time?

A: 12 months. Warranty part: the temperature control circuit board.

19. Q: Can I buy extra heating tubes for replacing?

A: Yes. We offer one standby heating tube for each ABM.

20. Q: Can I buy extra water pump for replacing?

A: Yes. You could buy any spare parts as you want.

21. Q: Where is the spare heating lamp in the package?

A: Spare heating lamp is packed into a silver or black alluminum alloy tube. Since it is fragile, it need special protection. Please be careful when you push out the heating lamp.

22. Q: How to exchange the heating lamp.

A: Firstly, turn off the machine power supply, to ensure the broken heating lamp is cooled enough. Open the metal set in both sides of the machine, take out the broken heating lamp, pull out and unfasten the wires. Then exchange the new heating lamp as it was. Please ask for sales for video guidance with any questions.

23. Q: Does the machine have CE certification?

A: Yes.Caution: To ensure the power supply is turned off, before cleaning and replairing.

Reviews

Download

-

The Sign-mate story began in 2009, when our founders decided on a simple and profound goal to provide small, sophisticated, easy-to-use sign-making tools for people who love the advertising sign industry. It is essential for us to know the people who need, use and buy our products.

In order to make meaningful and lasting connections with the people who use our products, and in order to make it more convenient for consumers to buy our products more quickly, we have set up a online shopping website www.sign-mate.com . More direct communication with them allows us to incorporate more of their experiences, setbacks, and goals into the development process. Based on their feedback, we have been able to make better products that have met their real needs.

Our products are centered on excellent quality and safety, ergonomic, comfortable, accessible and easy to use. In the work all has a good use experience which favored by a lot of users,.

Please note that any emails that we send to you should always indicate our website domain name, @sign-mate.com, and any payments made to us should be made only to the designated account on our website. If you find that any contacts or payment requests from our website are not from our designated email address or bank account, please contact us as soon as possible for clarification and confirmation.

We are committed to providing you with the best possible service and support. If you have any questions, comments, or concerns, please do not hesitate to contact us.